Description

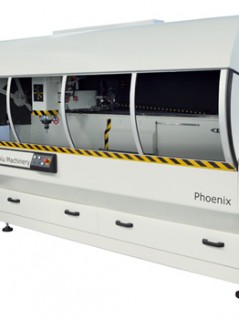

VERTICAL C.N.C. MACHINING CENTER

FOR COMPOSITE PANELS (ALUCOBOND) mod. MC 3416

for continuous faces, furniture, sky signs – mt. 6,60×2,15×2,40 –

Work field 3400x1575x100 mm.

VERTICAL C.N.C. MACHINING CENTER FOR COMPOSITE PANELS (ALUCOBOND)

mod. MC 3416

Reduced overall dimensions and maximum accessibility.

Monolithic structure electro-welded basement.

Closed bridge traverse “GANTRY”.

Axis movement by brushless motors and YASKAWA digital drives.

High production speed thanks to dedicated operator groups.

Facilitated programming by parametric macroes.

Software-integrated cad-cam and nesting.

Worktable and panels always clean thanks to the advanced suction system and

to chips fall by gravity.

PROGRAMMING SOFTWARES

Panel dimensions

– Box dimensioning

– Tongue height

– Additional workings

– Selection priority of workings

Hooking slot – Creation

– Creation files hooking slots

– Definition of geometrical parameters

– Export DXF for reinforcement plate

Hooking slot – Positioning

– Slot positioning on box tongues

– Possibility to choose the quantity of slots

– Possibility to choose slots previously created

Closing edge”Puzzle”

– Closing edge “PUZZLE” box

– Automatic parameters according to tongue height

Closing edge “Rivets”

– Closing edge “RIVET” box

– Automatic parameters according to tongue height

Nesting

– Working optimization with consequent reduction of wastes

– Optimization of plate direction

“V” milling

– Independent and dedicated group e dedicato for “V” milling for tongue plying.

Panel squaring

– Circular saw aggregate to cut and square composite panels (optional)

Angle milling and slot hooking

Shaped cutter, mounted on ISO 30 cone, available in tool store,

managed by the electro-chuck

Drilling for edges and rivets

Drilling bit mounted on ISO 30 cone, available in tool store, managed

by the electro-chuck 10-position tool store

STANDARD EQUIPMENT

Panel clamping

Transpirant worktable divided into 2 areas, with MDF martyr panel, for

panel vacuum clamping by means of vacuum pump 250 m³/h.

Gantry

Gantry type traverse with double motorization.

High rigidity and precision.

Control console

Industrial PC, Microsoft Windows XP, colour LCD 17″ monitor.

Ethernet connection, 4 USB doors, keyboard and mouse

Cad-cam ASPAN programming software.

TECHNICAL FEATURES

Work area: X 3400 – Y 1575 – Z 100 mm.

Wired worktable with MDF martyr panel: 3 vacuum panel clamping areas

Axis speed: X 60 – Y 40 – Z 10 mt/min.

Electro-chuck 5,5 kW – ISO 30 – 18.000 r.p.m.

10-position tool replacement store with cone presence sensor

Dedicated “V” milling group diam. 175 mm., Z 6+6, 6000 r.p.m.

Panel clamping by vacuum pump 1 x 250 m³/h

Total absorbed power 15 kW

Net weight about 3.200 Kg.

ON REQUEST

Remote control

Palmare CNI 850

Program starting

“JOG” manual axis control

“Override” speed control

Additional vacuum pump

Total 500 m³/h (250+250)

To work small panels

Uprated electro-chuck

7,5 kW ISO 30 – 18000 r.p.m.