Description

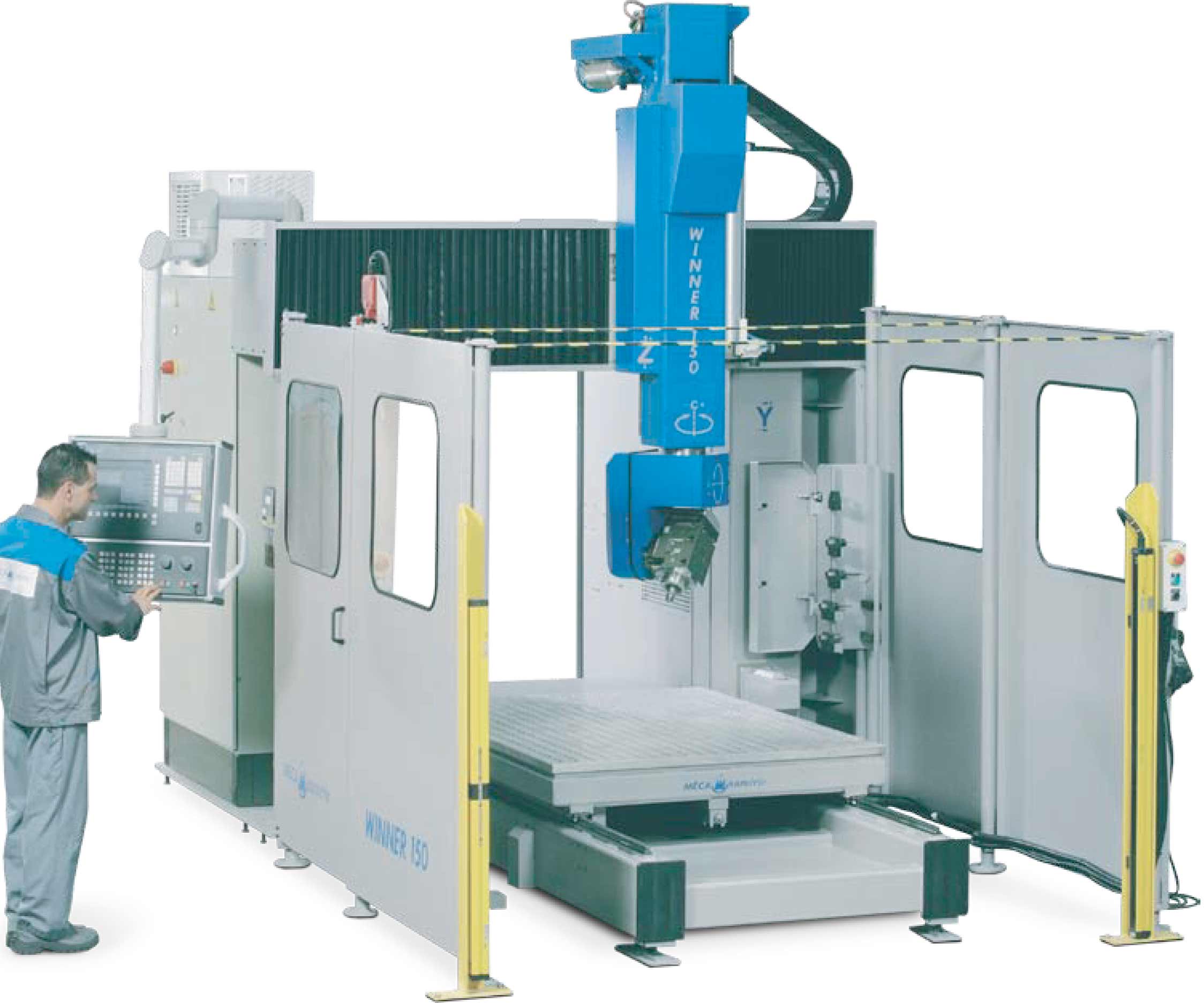

5-AXIS WORKING CENTER mod. WINNER 100 – As per E.C. rules

5-AXIS WORKING CENTER mod. WINNER 100 – As per E.C. rules

Line of 5-axis equipments featured by fixed gantry and mobile table

for machining with 3 or 5 axis.

A complete range of electro-spindkes allows specific workings

on plastic materials, composites or aluminium alloys.

The proposed sizes meet – for the most part – the working sizes

of thermo-forming presses.

Structure: Mechano-welded steel fixed gantry.

Table: Machined aluminium table (like option: bakelite or cast and machined phenolic resin).

Guides: Prismatic guides.

Transmission: Endless screw on X-Y-Z axis, turning ring nut for X-axis (mobile table).

On A-axis: YRT (INA) high rigidity combined movement, Brushless motor + pulley/belt transmission on quick level, reduction gear Harmonic Drive with very rigid hollow shaft.

On B-axis: spindle assembling on intermediate piece between a hollow

shaft reduction gear Harmonic Drive.

TECHNICAL DATA

– X-axis stroke 1510 mm.

– Y-axis stroke 1500 mm.

– Z-axis stroke 600 mm.

– C-axis stroke (rotation in degrees) ± 200 (I)

– A-axis stroke (rotation in degrees) ± 120 (I)

– max. speed in mm/sec (axis: X,Y and Z) 500 mm/sec

– max. speed in degrees/sec (axis: A and C) 180 °/sec

– resolution 0,002 mm.

– precision after linearity (per mt.) at 20°C ± 2° ± 0,08

– repeatibility in mm. at 20° C ± 2° ± 0,06

– automatic centralized greasing

– tool length measurement system, automatic caareening

– length 6140 mm.

– width 2630 mm.

– height (high Z /low Z) 2880/3485 mm.

– medium weight 8700 kg.

Pneumatic feeding: Pressure 6 bar / Min. delivery 30 cu.m./h

Electric feeding: 400 V . 3-phase – 50 Hz + earth – Power installed according to configurations

NUMERICAL CONTROL

• Numerical control SIEMENS SINUMERIK 840DI: X-Y-Z-C-A axis.

— STN 10.4″ colour screen OP010.

— Brushless motorization type 1FK7 with numerical variators.

— Air-conditioned electric box.

• Numerical control SIEMENS SINUMERIK 840DI: X-Y-Z-C-A axis.

— STN 10.4″ colour screen OP010.

— Brushless motorization type 1FT6 with numerical variators.

— Air-conditioned electric box.

• Numerical control NUM 1050 DIGITALE: X-Y-Z-C-A axis.

— TFT 12″ flat screen.

— MP03 operator’s keyboard.

— Brushless motorization type BPH with numerical variators.

— Air-conditioned electric box.

OPTIONS AND ACCESSORIES

– Suction tables

– IV250 (1 vacuum pump 250 m.c./h/ 11 kW)

– VACTS (1 turbine pump 1000 m.c./h/ 11 kW)

– Protection by photoelectric cells (EN 264 rule)

– Protection by manual doors (EN 264 rule)

– Automatic tool replacement with static 5-tool store