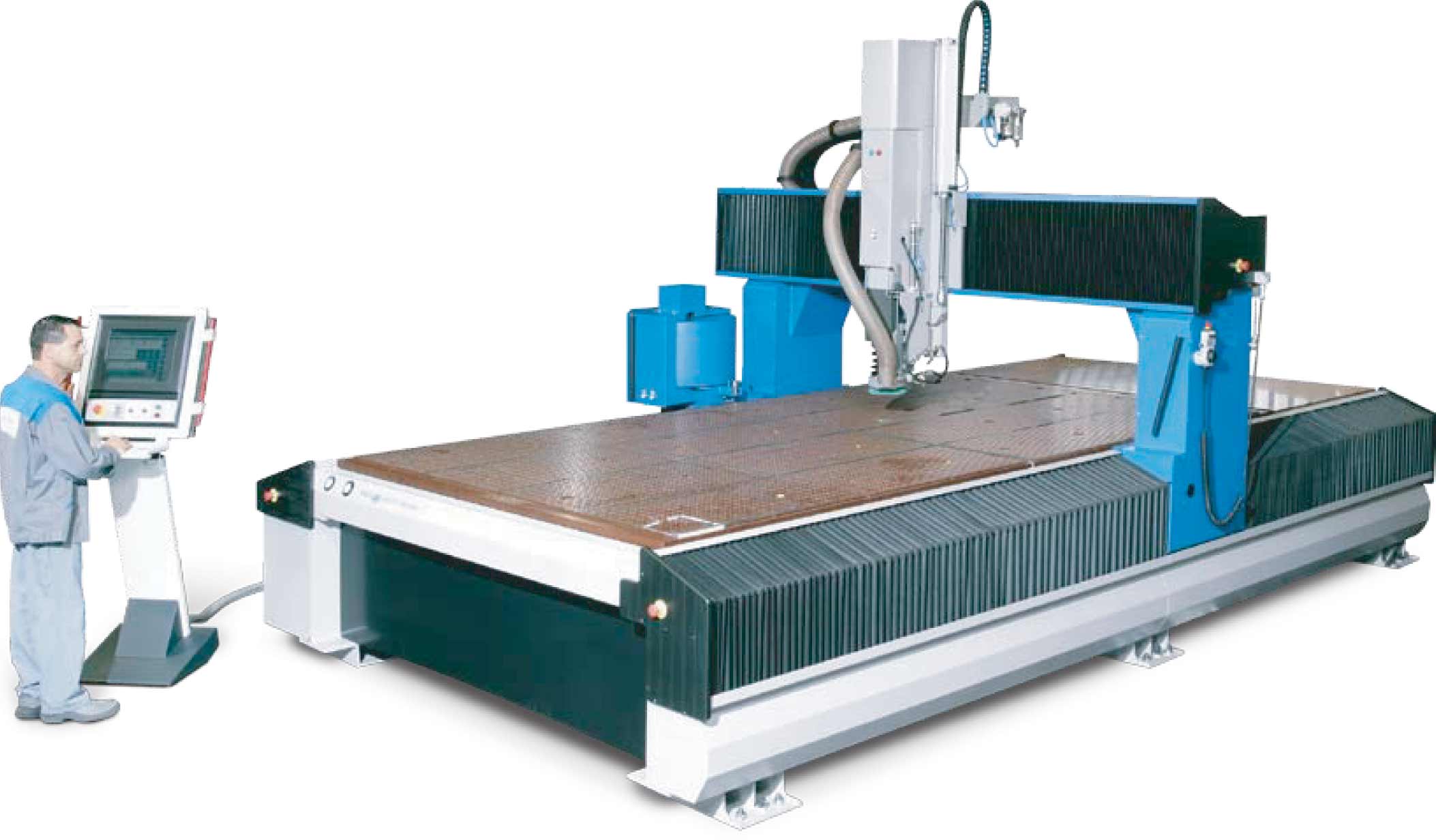

Description

CUTTING AND ENGRAVING MACHINE

“MECAPLUS” series mod. PLUS 3121X2 – As per E.C. rules

CUTTING AND ENGRAVING MACHINE

MECAPLUS series mod. PLUS 3121X2 – As per E.C. rules

DESCRIPTION

Structure: high inertia steel welded with strong sectione

Table top: aluminium fixed table with martyr coating or phenolic resin table

Guidance: prismatic guides

Transmission: endless screw on 3 axis with double screw for the X-axis.

Motorization: Brushless servo-motors

FEATURES

– max. speed: 500 mm/sec. on X, Y and 300 mm/sec. on Z-axis (STAR o REXROTH)

– repeatibility: ± 0,02 mm.

– absolute precision: ± 0,02 mm. per each mt. (after linearization)

– resolution: 0,001 mm.

– acceleration: from 1 to 3 mt/sec. according to the installed N.C.

– motorization: Brushless servo-motors 1000 W on X and Y, 300 W on Z-axis

– transmission: double endless screw D. 40 mm. on X1 and X2 axis; endless screw D. 32 mm. on the Y-axis, endless screw D. 25 mm. on the Z-axis

– guides: rectified rails and prismatic guides (STAR or REXROTH).

– frame and portal: welded and stabilized steel.

TECHNICAL DATA

– X-axis stroke mm. 3110

– Y-axis stroke mm. 2100

– Z-axis stroke (standard/option) mm. 275-500

– max. width of materials mm. 2300

– passage under gantry (standard/option) mm. 375-600

– max. speed 625 mm./sec.

– resolution in mm. 0,001

– repeatibility in mm. at 20° C ± 2° ± 0,02

– length mm. 4650

– width mm. 3600

– height mm. 3160

– medium weight kg. 6400

FEEDING

Pneumatic feeding – Pressure: 6 bar / Delivery from 6 to 40 mc/h

Electric feeding: 3-phase 400 V 50 Hz + ground – Power according to configurations

NUMERICAL CONTROL

– Control MECANUMERIC CN7100 ISO with fixed disc 40 Gb, MHI on mobile keyboard with 15 inches touch screen, data insertion with Ethernet connection

Options

– Numerical control SIEMENS SINUMErIK 840DI o 840 D

– Numerical control NUM 1040.

– Numerical control FANUC 160 I

OPTIONS

Valid only with NC SIEMENS 840 D or 840 DI and DELTA or HF 120 chucks with coder – FOR ALL MODELS

– 840-AUTO-NZ (Suction nose + pipes without tank nor pump).

– Rotary table (Dividing table + center, with Z500 option, only).

– 840 -ASSE A (4th axis ± 60° as to the vertical axis, with Z 500 and DELTA 10-R chuck, only)

– 840 -ASSE A+C (4th axis ± 60° as to the vertical axis + 5th axis ± 200° around the axis

OPTIONS AND ACCESSORIES

– Suction table 2V250 (2 vacuum pumps 250 mc/h 4,5 kW)

– VACT-12-10-2 (2 turbines 520 mc/h 7,5 kW)

– VACT-12-10-4 (4 turbines 520 mc/h 7,5 kW)

– LUB G640 (tool cooling – soluble oil vaporization 6 lts/h)

– AIRGEL (tool cooling by frozen air)

– ASP (professional chips suction unit 4 or 7.5 kW)

– ASPCYCL (cyclonic pre-filtering + tank 100 lts)

– Automatic tool change: rotative with 12-tool store

– Z500 (overhead portal, Z stroke: 500 mm.)